FIRE RATINGS

90 Minute Rating on the following: Singles up to 3’0″ x 8’0″ | Pairs up to 6’0″ x 7’0″

All of our 90 minute fire labels read: Listed Fire Door Frame | 1 1/2 Hour Rating | Minimum Jamb Depth 3 3/8 Inch | In Steel Stud, Wood Stud or Masonry | Meets UBC 7-2-97/UL 10C | Positive Pressure Requirements | Smoke and Draft Rating Requires Listed Gasket.

Listed Fire Door Frame | 1 1/2 Hour Rating | Minimum Jamb Depth 3 3/8 Inch | In Steel Stud, Wood Stud or Masonry | Meets UBC 7-2-97/UL 10C | Positive Pressure Requirements | Smoke and Draft Rating Requires Listed Gasket.

Per NFPA 80:3-6.1 Flush Mounted Doors. The non combustible clearance between the bottom of the flush-mounted doors and a raised non-combustible sill shall not exceed 3/8 inch. Where there is no sill, the maximum clearance between the bottom of the door and the floor shall not exceed 3/4 inch. Clearances at the meeting edges of doors in pairs shall not exceed 1/4 inch for three ply tin clad doors or 1/8 inch for other doors.

STRUCTURAL PERFORMANCE RATINGS AND IMPACT RATINGS

Superior closer insertion design: Design pressure ratings are available for compliance with national, state and local wind and/or missile requirements. Product approval under Florida Building Code or Intertek Testing Services/Warnock Hersey® validation program.

3’0 X 6’8 Single Door | 6’0 X 6’8 Double Door | 3’0 x 8’0 Single Door

Consult factory for supporting documentation.

IN-HOUSE CLOSURE TEST

During the development stages of our new adjustable kerf steel door frame it was important to ensure on a 90 minute application, the door would close and latch properly from a distance of 18”. Our first step was to develop the proper rabbet dimension, along with the right door seal. We used an adjustable stop, and two different profiles of door seals, 1/2” and 5/8”. After testing it was determined the 1/2” door seal (Schlegel Brand QEBD 5000) ensured a secure fit between the door and frame. In addition, it allowed for proper closing and latching. Our frame must utilize the 1/2” profile door seal.

The next step was to establish proper interference between the door and the sweep. Several sweeps were used, and required different clearances in order to ensure there was not excess interference which would create closure problems. It is important to consult the factory, and allow us to test your door and sweep to determine the proper interference.

Our TA-1 adjustable T-Strike comes standard with all of our frames, and allows for 1/4” of adjustment in the field.

All of the above will ensure an opening that closes and latches in the field every time.

Q-LON DOOR SEALS WEATHERSTRIPPING-QEBD500

Frame-Up™ uses Schlegel weatherstripping because of its superior performance and quality. Below are the specifications of the weatherstripping.

Download weatherstrip-qebd500.pdf

Standard Pack: 37″ (0.94m) 250 pcs/ctn; 82″ (2.08m) 125 pcs/ctn; 86″ (2.18m) 125 pcs/ctn; 97″ (2.46m) 125 pcs/ctn;

Standard Lengths: 37″(0.94m), 82″(2.08m), 86″(2.18m), 97″(2.46m). Tolerance +/-1″(25.4mm). Other lengths available upon request.

Fire Rating: UL rated up to 3 hours

Installation: One profile seals the strike side, hinge side, and header.

Special Features: Composed of open-celled foam and a polyethylene liner which provides maximum long term performance with low compression force, and resistance against compression set. Retains its original shape year after year to maintain an excellent weather seal. Covered under the Storm Shield Guarantee. Dual durometer insert allows for easy insertion and maximum retention. It is removable without damaging jamb or seal.

Other Information: Kerf Width 0.125″(3.2mm); Kerf Depth 0.438″(11.1mm); Rabbet Depth 1-15/16″(49.2mm); Reach 0.489″(12.4mm) The liner is exceptionally durable and extremely tough, plus paints and varnishes do not adhere to it. Additives in the liner inhibit the effects of UV light on Q-Lon weatherseals.CFC free. Also available in Duraclad Liner.

SPECIFICATION SHEETS

View/Download Specifications for Three and Four Hinge Frames pdf file.

HINGE AND STRIKE PREPS

STANDARD STRIKE PREPS

- The TA-1 Strike Prep can be placed at any location

- The Deadbolt Strike must be placed a minimum of 3 1/2″ from any other strike prep

ELECTRIC STRIKE PREP

- Other Strike Jambs will require a special prep.

- Consult the factory for a current list of preps, availability and cost

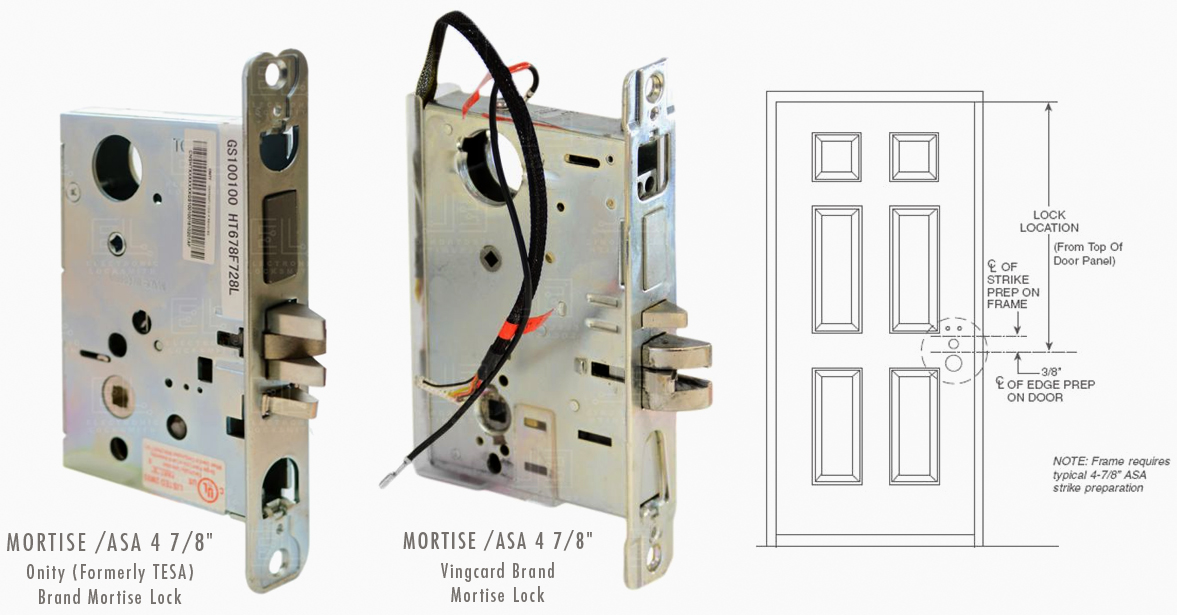

MORTISE LOCKS

D-STRIKE (FULL LIP)

Application:

- This prep enables the strike plate from the lockset to be applied to the frame.

- 1/4″ of adjustability allowing for proper door closure in the field.

- Superior to any other D-Strike prep in the field because of the profile. (No gap between the strike plate and the frame)